Well in an effort to be faithful with my board-proclaimed new years brewing resolutions, I have started working on the new milling cart. As I posted recently, I got a new Monster Mill MM 3 2.0 with hardened rollers. Since I sold my whole other mill, stand, motor, and the like, I have started from scratch. I gathered some good ideas and great scavenged stuff to build with, so I really dont mind starting over. It give me the change to build it stronger...faster....better. Its like the 6-million dollar grain mill. Hopefully, the cost will come in somewhat below that, but with projects at my house, you never know.Well here we go:1: So this is a great cart that I scavenged from the garbage. It's old but it is still in great shape. It is an all stainless steel lab cart as best I can tell.

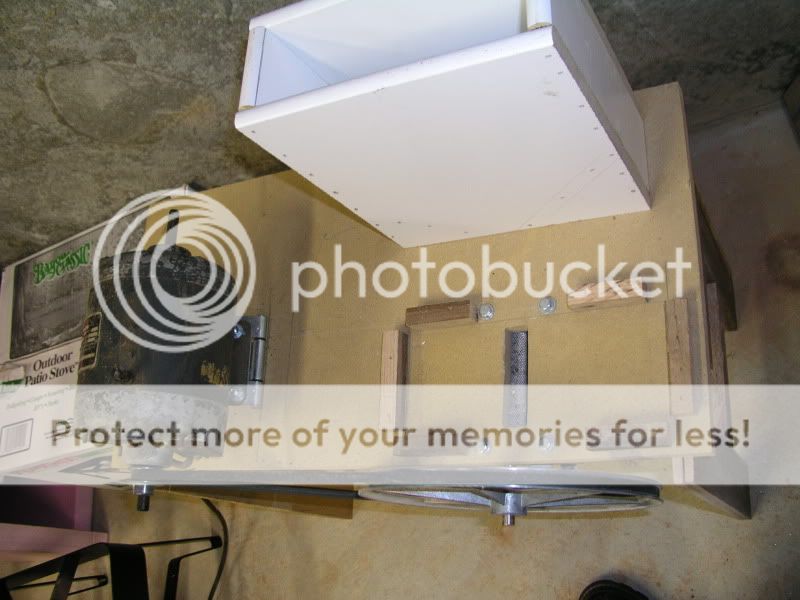

2: This is the cart with the holes drilled to mount the mill and the hole cut for the grain to come through. Yes I did it with the dremmel and a lot of those little cutting wheels.

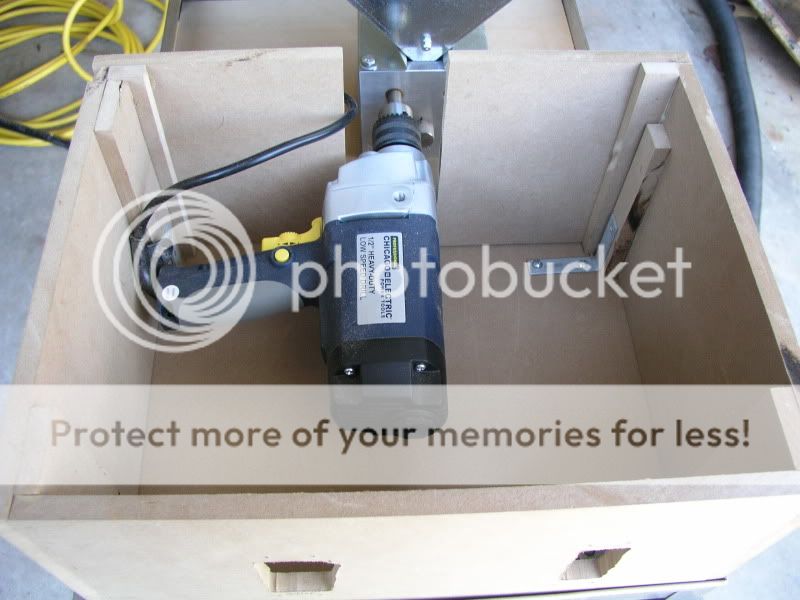

3: Now I have installed a piece of MDF (1/2") on the top with the same holes drilled and cut. In case you are wondering how I did it, I had one of the bases that came with the monster mill. So, I just drilled through the holes of that, bolted the base to my MDF, and then used a router with a straight bit and guide wheel to cut the big hole. This gave me pretty much and exact match of a pattern on my piece of MDF

2: This is the cart with the holes drilled to mount the mill and the hole cut for the grain to come through. Yes I did it with the dremmel and a lot of those little cutting wheels.

2: This is the cart with the holes drilled to mount the mill and the hole cut for the grain to come through. Yes I did it with the dremmel and a lot of those little cutting wheels. 3: Now I have installed a piece of MDF (1/2") on the top with the same holes drilled and cut. In case you are wondering how I did it, I had one of the bases that came with the monster mill. So, I just drilled through the holes of that, bolted the base to my MDF, and then used a router with a straight bit and guide wheel to cut the big hole. This gave me pretty much and exact match of a pattern on my piece of MDF

3: Now I have installed a piece of MDF (1/2") on the top with the same holes drilled and cut. In case you are wondering how I did it, I had one of the bases that came with the monster mill. So, I just drilled through the holes of that, bolted the base to my MDF, and then used a router with a straight bit and guide wheel to cut the big hole. This gave me pretty much and exact match of a pattern on my piece of MDF