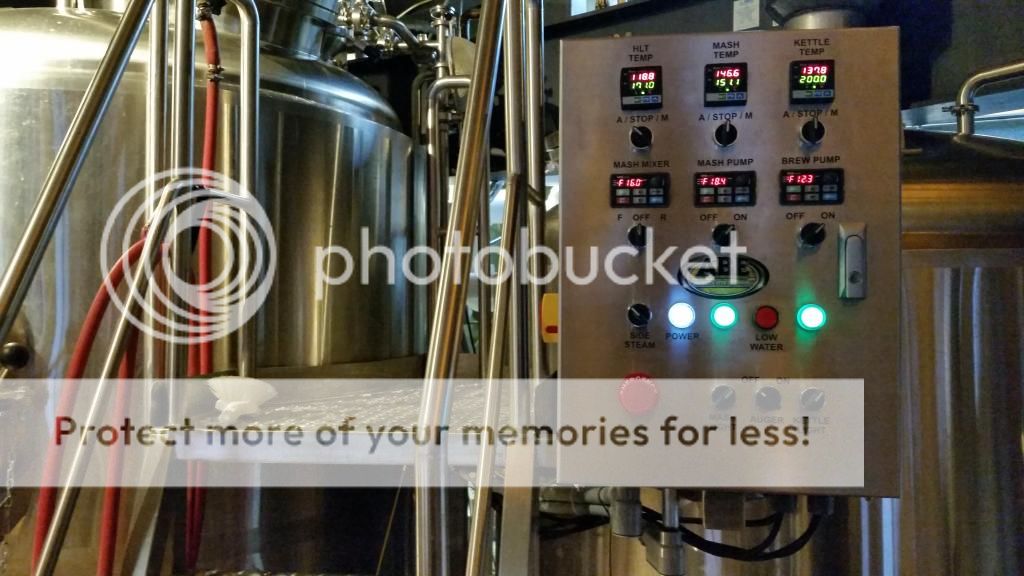

Had a great last few days brewing thought Id post a few pics. I brewed 15bll of my Altbier at one of our local pub's. The head brewmaster used my recipe and let me call how I wanted to handle the entire beer. I got some good hands on with the system and got to push a few buttons but I still didn't know how to run it. But by the end I had an idea how the plumbing worked. Great opportunity and cant wait to try it.

Neat little video mashing in

https://vid113.photo...zpsffvh7yqh.mp4

Look at that mash temp! Cant beat that for a Altbier!

A few days later it was barrel brew day. We decided to revisit an old friend and do 60g of our Brett BGS. Hit all our numbers. Another great day!

Added all the extensions to make this 80g. Not a big fan of how tall this thing gets. But we got it stable. No temp control as we chilled mid 60's then we will capture the rate of rise with some heating pads if we need to. Used a fresh 2bll pitch of Breendonk from BSI. Great few days of brewing!!